Pre-Project Technical Support

- Baghouse operating condition assessment

- Filter media recommendation

- Sample testing & trial installation

At Omela, we provide full life-cycle support for your industrial dust collection system—from consultation and design to production, installation, commissioning, optimization, and long-term maintenance.

Our engineers ensure that every filter bag, filter cage, filter housing, and filtration component performs reliably in demanding environments. With standardized QC processes, on-site service capability, and continuous monitoring support, we help you achieve cleaner air, lower operating costs, and longer system performance life.

Manufacturing high-quality industrial filter bags requires precision, consistency, and strict quality control at every step.

From raw filter media preparation to final packaging, Omela’s production follows a standardized workflow to ensure durability, filtration performance, and compliance with demanding industrial standards.Each filter bag is crafted by skilled technicians using advanced equipment, ensuring excellent sealing, accurate dimensions, and long service life.

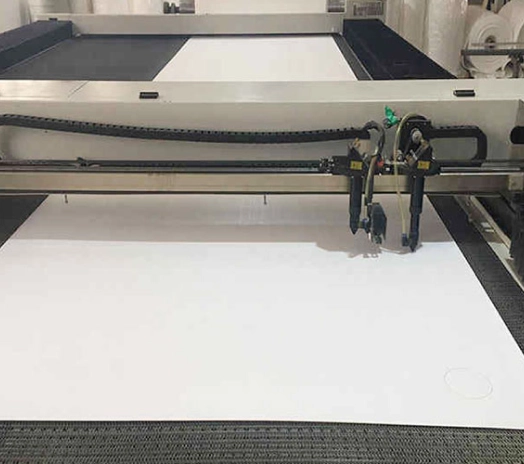

Precisely cutting roll filter media using automated cutting machines to ensure accurate bag dimensions and consistent performance.

Sewing the bag body with reinforced stitching to ensure structural strength and resistance to mechanical stress.

Attaching the bag’s top components such as snap band, flange, or steel ring to ensure perfect fit with the dust collector.

Attaching the bag’s top components—such as plastic collar, steel ring, or flange—to ensure a secure, leak-free seal with the liquid filter housing.

Adding reinforcement layers, anti-wear patches, or protective components to improve durability in heavy-duty applications.

Securing the bottom end (welded, sewn, or sealed) to ensure airtight performance and prevent dust leakage.

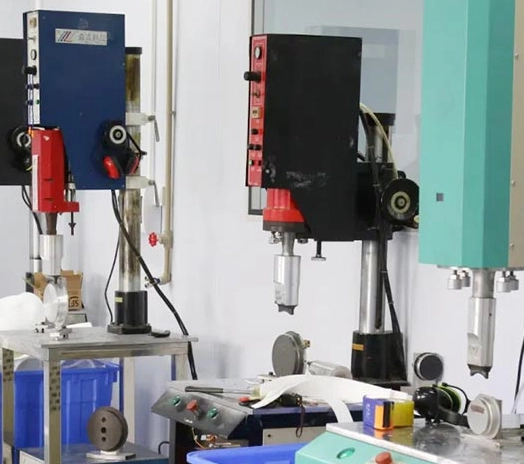

Applying thermal or ultrasonic sealing on stitch lines to increase filtration efficiency and eliminate needle-hole leakage.

Adding heat-resistant sealing tape to critical seams for enhanced dust-tightness and long-term durability.

Performing full inspection—including size measurement, tensile testing, stitching strength, and leak check—to guarantee product quality.

Packing filter bags in clean, moisture-proof packaging to ensure safe transportation and contamination-free delivery.

Experienced engineers supporting your project from start to finish.

Tailor-made filtration solutions for your exact equipment and application.

Standardized workflows, strict QC, and on-time global delivery.

Advanced lab testing, material development, and performance optimization.

Private labeling, design support, and fully customized production.

Fast response, technical guidance, and lifetime service assurance.

Longer bag life, fewer change-outs, and lower total cost of ownership (TCO). Let our experts show you how much you can save.

Absolutely. We provide full OEM/ODM filter bag customization, including:

This service helps clients developing new filtration systems or upgrading existing dust collectors.

Yes, we offer free samples for most standard materials and bag configurations.

For customized bags, we can produce a trial sample within a few days for performance and fit testing in your baghouse system.

We provide complete engineering support:

This ensures you choose the best filter bag solution for long-term performance.

Yes. Our team provides:

Proper maintenance extends filter bag life and improves dust collector efficiency.

We conduct strict testing and quality control, including:

Every filter bag is inspected before shipment to guarantee reliable performance.

Yes. Installation support is available through:

We ensure smooth and correct installation to avoid leakage or premature bag failure.

For common materials (PPS, PTFE, aramid, polyester, fiberglass), samples are normally ready within 3–5 days.

Standard bulk orders ship within 7–15 days, depending on quantity and customization level.

We provide full lifecycle service, including:

This keeps your dust collection system running efficiently while reducing operational cost.