Material & Application Consultation

- Fiber selection based on temperature & chemical resistance

- Matching felt type to industry needs (cement, asphalt, power, metallurgy)

- Sample supply for performance validation

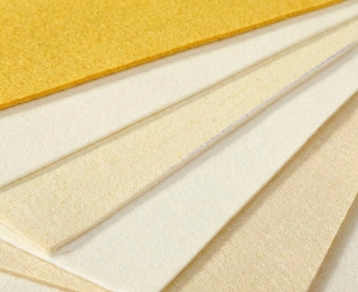

Needle-punched felt is a non-woven industrial filtration media made by mechanically interlocking fibers into a dense three-dimensional structure. The unique depth-filtration mechanism enables superior dust-loading capacity, stable differential pressure, and reliable performance in pulse-jet and reverse-air baghouses.

A properly designed needle-punched felt bag delivers:

Better stability, longer lifetime, and fewer cleaning cycles combine to lower maintenance cost, compressed-air usage, and downtime.

| Material | Working Temperature | Instant Temperature | Abrasion Resistance | Hydrolysis Resistance | Acid Resistance | Alkali Resistance | Oxidation Resistance | Relative Cost |

|---|---|---|---|---|---|---|---|---|

| Polypropylene Needle Felt | 90°C | 110°C | Good | Excellent | Excellent | Excellent | Middle | $ |

| Polyester Needle Felt | 130°C | 150°C | Excellent | Poor | Middle | Fair | Good | $ |

| Acrylic Needle Felt | 120°C | 130°C | Middle | Good | Good | Middle | Good | $$ |

| PPS Needle Felt | 180°C | 200°C | Good | Excellent | Excellent | Excellent | Fair | $$$ |

| Aramid Needle Felt | 204°C | 220°C | Good | Middle | Middle | Good | Middle | $$$ |

| Fiberglass Needle Felt | 250°C | 280°C | Fair | Good | Middle | Fair | Good | $$$ |

| P84 Needle Felt | 240°C | 260°C | Good | Middle | Middle | Middle | Good | $$$$ |

| PTFE Needle Felt | 250°C | 280°C | Good | Excellent | Excellent | Excellent | Excellent | $$$$ |

Needle-punched felt is widely used across medium and heavy industries requiring stable particulate control, high filtration efficiency, and reliable baghouse performance.

Needle-punched felt performs reliably under high dust loading and temperature fluctuations, ensuring stable pressure drop and long service life in kiln and clinker cooler baghouses.

Read MoreThe carbon black industry produces one of the most challenging dust environments in industrial filtration due to the extremely fine particulate nature.

Read MoreNeedle-punched felt provides reliable filtration in high-temperature, corrosive flue gas environments, maintaining low emissions and long bag life in coal-fired boiler baghouses.

Read MoreTypical filtration efficiency achieved with needle-punched felt media based on PPS, Aramid, Fiberglass and PTFE fibres in well-designed baghouses.

Lower average pressure drop when upgrading from basic or woven media to optimized needle-punched felt and correctly engineered air-to-cloth ratios.

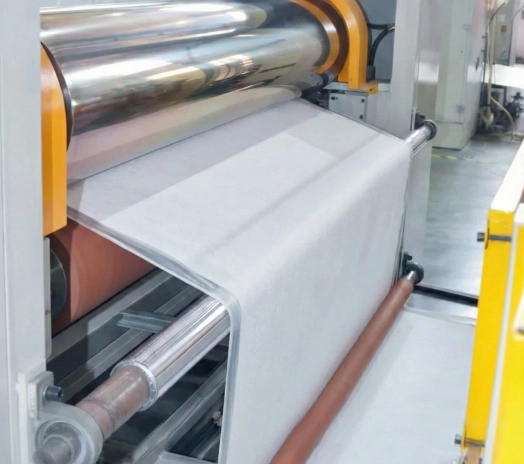

Manufacturing high-quality needle-punched felt for industrial filter bags demands precise fibre control, consistent needling density, and strict in-process quality checks at every station. The goal is a stable, uniform felt with predictable permeability and mechanical strength in real baghouse conditions.

From fibre opening and carding, through cross-lapping, needle punching, heat setting, and surface finishing, Omela follows a standardized workflow to guarantee durability, filtration performance, and dimensional stability. Each roll of felt is produced on advanced lines, then converted into filter bags with accurate cutting, stitching, and sealing—ensuring tight fit on cages, reliable operation, and long service life.

Opening compressed fiber bales and loosening fiber tufts to ensure a stable, uniform feed into the needle-punched felt production line.

Further separating individual fibers and removing coarse impurities to improve fiber cleanliness and prepare for accurate blending.

Precisely mixing different fiber types and deniers according to the media recipe to achieve consistent basis weight, permeability, and temperature resistance.

Using precision opening units to fully individualise fibers and achieve excellent dispersion before forming the web.

Aligning and combing fibers into a uniform single-layer web, controlling thickness, evenness, and fiber orientation for stable mechanical properties.

Continuously laying the carded web onto a conveyor to build the target basis weight and create a stable substrate for crosslapping and needle punching.

Stacking multiple web layers at controlled angles to enhance strength in both machine and cross directions and improve felt uniformity.

Using barbed needles to repeatedly punch through the fiber web, mechanically entangling fibers into a dense three-dimensional needle-punched felt structure.

Inspecting thickness, weight, surface quality, and defects on-line, then winding the felt into rolls for downstream thermal and surface treatments.

Stabilising the felt under controlled temperature and tension to reduce residual shrinkage and lock in dimensional stability for high-temperature service.

Optimising the surface by gas singeing and/or calendering to remove loose fibers, smooth the face, and improve dust release and filtration efficiency.

Laminating a microporous PTFE membrane or other functional layer onto the felt to create surface-filtration media with ultra-low emissions and fast pulse cleaning.

The performance of needle-punched felt depends heavily on the selected fiber. Key factors: temperature resistance, abrasion resistance, hydrolysis stability, chemical resistance, and oxidation resistance .

Different applications require specific felt densities and structural designs. Higher weights typically offer better durability and lower emissions, while lighter felts provide higher permeability for low-pressure systems.

Surface treatments enhance filtration efficiency and service life.Typical finishes include: singeing, calendering, heat-setting, anti-static treatment, oil & water repellent, PTFE impregnation, PTFE membrane.

A well- engineered felt must maintain integrity under pulse-jet cleaning and high dust loading.Critical factors: tensile strength, elongation, heat shrinkage, and internal bonding strength developed during needle-punching.

Choose felt according to process conditions: temperature peaks, moisture level, acid/alkali concentration, corrosive flue gas, and dust abrasiveness. Matching the right felt significantly reduces pressure drop, downtime, and operating cost.

Choosing the right filtration supplier affects everything from system stability to maintenance downtime. At Omela Filtration, we combine reliable materials, controlled production, and years of industry experience to support dust and liquid filtration needs across different plants and applications.

We use consistent-grade filter media, sewing thread and metals sourced from qualified suppliers. Each batch is checked for weight, thickness, air permeability and tensile strength to keep performance steady across shipments.

Our facility is equipped with modern sewing lines, hot-welding machines and automated inspection tools. This keeps production efficient and helps us meet tight delivery schedules, even on custom orders.

Our engineers and technicians have long experience with dust collectors, liquid systems and industry-specific conditions. They help you match materials to temperature, chemistry and air-to-cloth ratios to avoid unnecessary failures.

From sampling to documentation and shipping, our team responds quickly and keeps information clear. Customers in cement, asphalt, power and water-treatment plants rely on our service to resolve problems without delay.

From the first technical discussion to installation and long-term maintenance, our team stays involved at every stage. We analyze your operating conditions, adjust product designs when needed, and ensure the final filtration setup works reliably in real plant environments. After delivery, our service team continues to provide guidance and troubleshooting support, helping you keep your system stable and downtime low.

Needle-punched felt is made from randomly oriented fibers mechanically bonded by needling, offering:

Woven fabrics are structured, smoother, and used more in liquid filtration or specific industrial processes. Needle-punched felt is the standard for dust collector bags.

| Operating Temperature Range | Recommended Needle-Punched Felt Material |

|---|---|

| Below 120°C | Polyester (PE) / Polypropylene (PP) |

| Up to 150°C | High-Grade Polyester |

| 150–180°C | Acrylic (PAN) / PPS (Ryton) |

| 180–220°C | Aramid (Nomex) |

| 220–260°C | P84 Needle Felt |

| Above 260°C | PTFE Needle Felt |

Choose PTFE-membrane felt when:

P84 or PPS with PTFE membrane is commonly used in cement, waste-to-energy, and chemical plants.

Higher needling density results in:

Lower needling density gives:

We customize the felt structure to match your dust characteristics and air-to-cloth ratio.

Yes — all fibers have a thermal shrinkage range. Typical shrinkage at working temperature:

We supply complete specifications including:

OEM/ODM customization is available.

Yes. We customize:

We also support OEM roll-goods supply for bag manufacturers.

Yes — small sample rolls, sheets, or trial bags can be provided for onsite testing before mass production.

With 20+ years of filtration know-how and hundreds of projects in cement, power, steel and asphalt, we engineer needle-punched felt media that deliver stable differential pressure, low emissions and reliable baghouse performance.