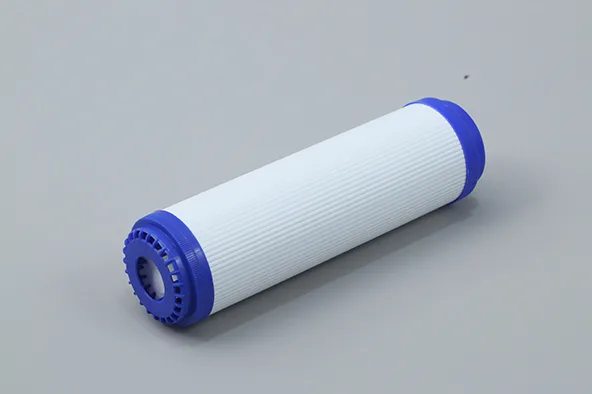

High Flow Filter Cartridges are large-diameter, pleated liquid filter elements designed to handle very high flow rates with fewer cartridges and smaller housings. They are ideal for RO pre-treatment, desalination, power plants, chemicals, food & beverage, pharmaceuticals, and general industrial water systems.

When selecting High Flow Filter Cartridges, engineers should balance:

- Micron rating: typically 1–100 µm for turbidity and particle control

- Flow rate & pressure drop: required system flow vs. allowable ΔP

- Fluid chemistry & temperature: compatibility of PP, PES, fiberglass, stainless steel, etc.

- Cartridge configuration: inside-out vs outside-in flow, end-cap style, O-ring material

- Target service life: dirt-holding capacity, change-out interval, and maintenance strategy

Omela High Flow Filter Cartridges deliver maximum flow per element, lower operating cost per m³, and reliable protection for critical process equipment in demanding liquid-filtration duties.