Pre-Project Technical Support

- Baghouse operating condition assessment

- Filter media recommendation

- Sample testing & trial installation

A dust filter bag is a high-performance textile element used inside a baghouse dust collector to separate fine particulate from industrial process air. As dirty gas flows through the filter media, dust forms a stable “dust cake” on the surface, which performs the actual filtration.

The combination of filter media properties, air-to-cloth ratio, operating temperature, chemical composition, and cleaning method determines how well the filter bag performs.

A well-engineered filter bag ensures:

Industrial dust filtration relies heavily on well-designed, properly selected, and precisely manufactured dust filter bags. As the core component of a baghouse system, filter bags directly determine dust collection efficiency, emission levels, energy consumption, and overall system stability.

Better filtration performance directly lowers total operating cost (TOC) year-over-year from Omela.

| Material | Working Temperature | Instant Temperature | Abrasion Resistance | Hydrolysis Resistance | Acid Resistance | Alkali Resistance | Oxidation Resistance | Relative Cost |

|---|---|---|---|---|---|---|---|---|

| Polypropylene Needle Felt | 90°C | 110°C | Good | Excellent | Excellent | Excellent | Middle | $ |

| Acrylic Needle Felt | 120°C | 130°C | Middle | Good | Good | Middle | Good | $$ |

| Polyester Needle Felt | 130°C | 150°C | Excellent | Poor | Middle | Fair | Good | $ |

| PPS Needle Felt | 180°C | 200°C | Good | Excellent | Excellent | Excellent | Fair | $$$ |

| Aramid Needle Felt | 204°C | 220°C | Good | Middle | Middle | Good | Middle | $$$ |

| P84 Needle Felt | 240°C | 260°C | Good | Middle | Middle | Middle | Good | $$$$ |

| PTFE Needle Felt | 250°C | 280°C | Good | Excellent | Excellent | Excellent | Excellent | $$$$ |

| Fiberglass Needle Felt | 250°C | 280°C | Fair | Good | Middle | Fair | Good | $$$ |

| Woven Fiberglass Filter Cloth | 260°C | 280°C | Good | Good | Good | Good | Good | $$$ |

Filtration needs vary from one plant to another, but the goal is the same—stable operation and clean output. Our products are used across different industries with demanding working conditions.

High dust load and rapid temperature changes make cement production a tough environment. Our filter bags, cages, and pulse-jet systems help maintain stable emission levels from kilns, mills, and clinker coolers.

Read MoreWaste-to-energy (WTE) plants face highly variable flue gas conditions due to inhomogeneous fuel quality.A well-designed baghouse system acts as the primary barrier for solid substances

Read MoreCoal-fired and biomass power stations require filtration materials that can tolerate high temperatures and fly ash. PPS, P84, and PTFE bags are often used in boilers, economizers, and dust collection units.

Read MoreBased on performance comparison of PPS, Aramid, Fiberglass, and PTFE.

Due to optimized media selection and air-to-cloth ratio.

Manufacturing high-quality industrial filter bags requires precision, consistency, and strict quality control at every step.

From raw filter media preparation to final packaging, Omela’s production follows a standardized workflow to ensure durability, filtration performance, and compliance with demanding industrial standards.Each filter bag is crafted by skilled technicians using advanced equipment, ensuring excellent sealing, accurate dimensions, and long service life.

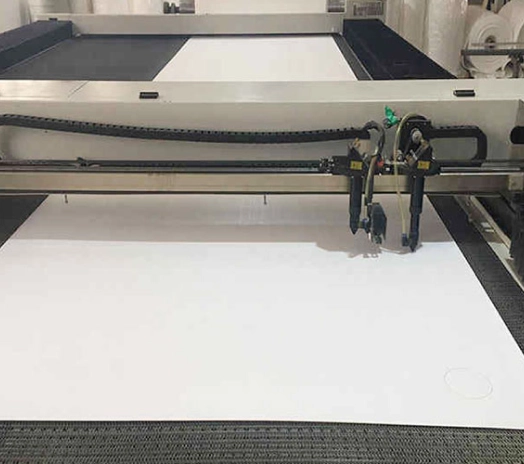

Precisely cutting roll filter media using automated cutting machines to ensure accurate bag dimensions and consistent performance.

Sewing the bag body with reinforced stitching to ensure structural strength and resistance to mechanical stress.

Attaching the bag’s top components such as snap band, flange, or steel ring to ensure perfect fit with the dust collector.

Attaching the bag’s top components—such as plastic collar, steel ring, or flange—to ensure a secure, leak-free seal with the liquid filter housing.

Adding reinforcement layers, anti-wear patches, or protective components to improve durability in heavy-duty applications.

Securing the bottom end (welded, sewn, or sealed) to ensure airtight performance and prevent dust leakage.

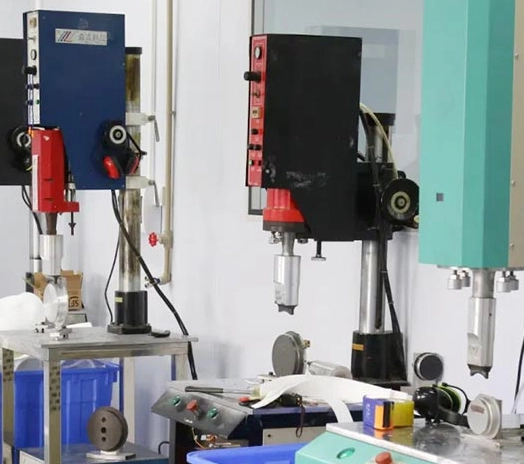

Applying thermal or ultrasonic sealing on stitch lines to increase filtration efficiency and eliminate needle-hole leakage.

Adding heat-resistant sealing tape to critical seams for enhanced dust-tightness and long-term durability.

Performing full inspection—including size measurement, tensile testing, stitching strength, and leak check—to guarantee product quality.

Packing filter bags in clean, moisture-proof packaging to ensure safe transportation and contamination-free delivery.

The characteristics of your dust determine the required filter media. Key factors: particle size, abrasiveness, chemistry, moisture/oil content, and operating temperature .

Each media offers different temperature, chemical, and mechanical performance. Common choices: Polyester, Polypropylene, Aramid, PPS, Fiberglass, PTFE.

Treatments that improve efficiency and extend service life: PTFE membrane, singed/glazed surface, calendering, anti-static, oil & water repellent .

Proper construction ensures efficiency and durability.Includes: top and bottom designs, stitching type, reinforcement, seam sealing/taping .

The A/C ratio affects airflow, bag life, and system performance. Choosing the right ratio reduces pressure drop, energy consumption, and extends filter life.

Choosing the right filtration supplier affects everything from system stability to maintenance downtime. At Omela Filtration, we combine reliable materials, controlled production, and years of industry experience to support dust and liquid filtration needs across different plants and applications.

We use consistent-grade filter media, sewing thread and metals sourced from qualified suppliers. Each batch is checked for weight, thickness, air permeability and tensile strength to keep performance steady across shipments.

Our facility is equipped with modern sewing lines, hot-welding machines and automated inspection tools. This keeps production efficient and helps us meet tight delivery schedules, even on custom orders.

Our engineers and technicians have long experience with dust collectors, liquid systems and industry-specific conditions. They help you match materials to temperature, chemistry and air-to-cloth ratios to avoid unnecessary failures.

From sampling to documentation and shipping, our team responds quickly and keeps information clear. Customers in cement, asphalt, power and water-treatment plants rely on our service to resolve problems without delay.

From the first technical discussion to installation and long-term maintenance, our team stays involved at every stage. We analyze your operating conditions, adjust product designs when needed, and ensure the final filtration setup works reliably in real plant environments. After delivery, our service team continues to provide guidance and troubleshooting support, helping you keep your system stable and downtime low.

Absolutely. We provide full OEM/ODM filter bag customization, including:

This service helps clients developing new filtration systems or upgrading existing dust collectors.

Yes, we offer free samples for most standard materials and bag configurations.

For customized bags, we can produce a trial sample within a few days for performance and fit testing in your baghouse system.

We provide complete engineering support:

This ensures you choose the best filter bag solution for long-term performance.

Yes. Our team provides:

Proper maintenance extends filter bag life and improves dust collector efficiency.

We conduct strict testing and quality control, including:

Every filter bag is inspected before shipment to guarantee reliable performance.

Yes. Installation support is available through:

We ensure smooth and correct installation to avoid leakage or premature bag failure.

For common materials (PPS, PTFE, aramid, polyester, fiberglass), samples are normally ready within 3–5 days.

Standard bulk orders ship within 7–15 days, depending on quantity and customization level.

We provide full lifecycle service, including:

This keeps your dust collection system running efficiently while reducing operational cost.

With 20+ years of experience and 1000+ global clients, we deliver stable filtration performance and dependable dust-collector operation.