Pre-Project Technical Support

- Liquid properties & contamination assessment

- Micron rating & media selection consultation

- Sample testing and pilot evaluation

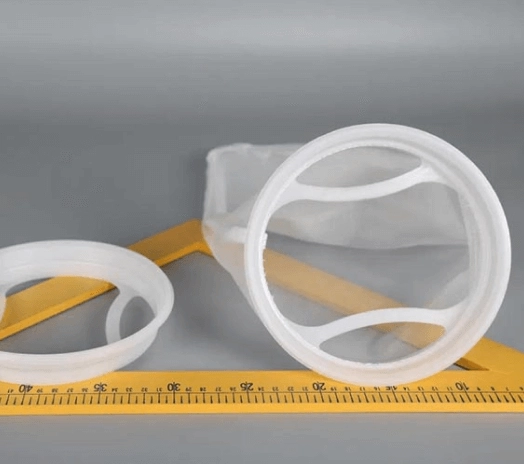

A liquid filter bag is a high-performance filtration element installed inside a bag filter housing to remove suspended solids, gels, particles, oil droplets, or contaminants from industrial process liquids. As liquid flows through the filter media, particles are captured either on the surface (mesh) or within the depth of the felt structure, delivering reliable clarification and process protection.

The effectiveness of a liquid filter bag depends on media selection, micron rating, permeability, chemistry compatibility, temperature limits, and how well the bag fits and seals inside the housing.

A well-engineered liquid filter bag ensures:

Industrial liquid filtration relies heavily on proper media selection, correct micron rating, and a precisely manufactured filter bag. As the core component of a liquid filtration system, filter bags directly affect filtration efficiency, system reliability, and operating costs.

Better filtration performance and longer service life significantly reduce annual operating cost (TOC) when switching to engineered liquid filter bags from Omela Filtrations.

| Material | Chemical Resistance | Temperature Resistance | Durability |

|---|---|---|---|

| Polypropylene | Good (most chemicals) | Up to 82 °C (180 °F) | Moderate |

| Polyester | Fair (some solvents) | Up to 100 °C (212 °F) | High |

| Nylon | Excellent (most chemicals) | Up to 120 °C (248 °F) | High |

| Fiberglass | Excellent (most chemicals) | Up to 260 °C (500 °F) | Very High |

| Model | Filter area (m2/pcs) | Volume (L) | Diameter | Length | ||

|---|---|---|---|---|---|---|

| cm | inch | cm | inch | |||

| Type 1 | 0.19 | 7.9 | 17.8 | 7 | 40.65 | 16 |

| Type 2 | 0.41 | 17.3 | 17.8 | 7 | 81.3 | 32 |

| Type 3 | 0.05 | 1.4 | 10.2 | 4 | 20.9 | 8.25 |

| Type 4 | 0.09 | 2.5 | 10.2 | 4 | 35.5 | 14 |

| Grade | Level 1 (μm) | Level 2 (μm) | Level 3 (μm) | Level 4 (μm) |

|---|---|---|---|---|

| Pore size | 1.5 10 25 50 | 80 100 125 150 | 200 250 300 350 | 400 500 600 800 |

| Material Available | Maximum Operating Temperature | Micron Rating (um) |

|---|---|---|

| Nylon (NMO) | 135–149°C | 5, 10, 25, 50,100, 150 ,200, 300, 400, 500, 600 |

| Polyester (PE) | 135–162°C | 0.5, 1, 3, 5, 10, 25, 50, 75, 100, 125, 150, 200, 250, 300 |

| Polypropylene (PP) | 93–104°C | 0.5, 1, 3, 5, 10, 25, 50, 75, 100,125, 150, 200, 250, 300 |

| Polytetrafluoroethylene (PTFE) | 250–300°C | 0.5, 1, 3, 5, 10, 25, 50, 75, 100,125, 150, 200, 250, 300 |

| Fiber Material | PE | Nylon | PP | PTFE |

|---|---|---|---|---|

| Abrasion Resistance | Very Good | Excellent | Very Good | General |

| Weakly Acid | Very Good | General | Excellent | Excellent |

| Strongly Acid | Good | Poor | Excellent | Excellent |

| Weakly Alkali | Good | Excellent | Excellent | Excellent |

| Strongly Alkali | Poor | Excellent | Excellent | Excellent |

| Solvent | Good | Good | General | Excellent |

Filtration requirements vary widely across liquid-processing industries, but the goals remain the same—stable flow, product purity, and lower operating cost.Omela liquid filter bags are trusted across multiple sectors handling water, chemicals, food, oils, coatings, and complex process liquids.

High solids load, variable feedwater quality, and strict discharge requirements make water treatment a demanding filtration environment.Omela PP and PE felt filter bags provide reliable removal of suspended solids, sand, rust, and oil-in-water contaminants—ideal for RO pre-filtration, recycle water, and polishing stages.

Read MoreFood and beverage plants require filtration that protects taste, clarity, and hygiene while complying with regulatory standards.Nylon monofilament and food-grade felt bags from Omela ensure stable particle removal for syrups, wine/beer, edible oils, dairy, and ingredient processing.

Read MoreChemical processes involve corrosive media, solvents, and high-temperature streams. Omela PP, PE, PTFE, and stainless steel bags deliver reliable particle control in plating baths, acids/alkalis, resin production, catalyst recovery, and solvent filtration.

Read MoreMulti-layer felt and mesh media ensure reliable particle removal across water, chemicals, oils, solvents, and food-grade liquids in micron ranges from 1–1000 μm.

Optimized pore structure and increased effective area reduce ΔP, extend bag life, and improve system stability in high-flow process lines handling water, chemicals, and viscous liquids.

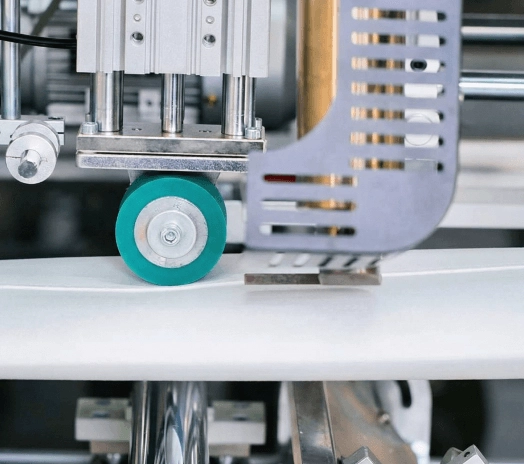

Manufacturing high-quality liquid filter bags requires precise media selection, consistent workmanship, and rigorous quality control at every stage.

From raw media preparation to final packaging, Omela’s production follows a standardized workflow to ensure stable micron ratings, reliable sealing, and long service life in demanding liquid-filtration duties. Every bag is produced by trained technicians using purpose-built equipment, so dimensions, welds or seams, and gasket fits remain consistent from batch to batch.

Precisely cutting roll media according to bag size and tolerance to ensure accurate diameter, length, and micron performance.

Joining side seams and bottoms by ultrasonic welding or industrial sewing to achieve strong, leak-free bag construction.

Attaching steel rings or molded plastic flanges with the specified O-ring or gasket to guarantee secure, bypass-free sealing in the housing.

Checking dimensions, seams, and surface defects before packing each bag in clean, protective packaging ready for shipment.

Understanding liquid characteristics is essential for selecting the right filter bag. Key factors: viscosity, particle load, pH/chemistry, oil or solvent content, and operating temperature.

Different media provide specific chemical, temperature, and mechanical performance. Common choices: Polypropylene (PP), Polyester (PE), Nylon/Monofilament Mesh, PTFE, Stainless Steel Mesh.

Selecting the correct micron rating depends on filtration goals. Typical ranges: 1–10 μm polishing, 10–50 μm intermediate, 50–1000 μm coarse. Consider whether a nominal or absolute rating is required.

Proper construction ensures sealing performance and prevents bypass. Key elements: steel/plastic ring or flange, O-ring type (EPDM/NBR/FKM/PTFE), multi-layer structure, stitching or welded seams.

Liquid viscosity and system flow determine ΔP and filter life. Choosing the right configuration reduces pressure drop, pump load, energy consumption and extends service cycles.

Choosing the right filtration supplier affects everything from system stability to maintenance downtime. At Omela Filtration, we combine reliable materials, controlled production, and years of industry experience to support dust and liquid filtration needs across different plants and applications.

We use consistent-grade filter media, sewing thread and metals sourced from qualified suppliers. Each batch is checked for weight, thickness, air permeability and tensile strength to keep performance steady across shipments.

Our facility is equipped with modern sewing lines, hot-welding machines and automated inspection tools. This keeps production efficient and helps us meet tight delivery schedules, even on custom orders.

Our engineers and technicians have long experience with dust collectors, liquid systems and industry-specific conditions. They help you match materials to temperature, chemistry and air-to-cloth ratios to avoid unnecessary failures.

From sampling to documentation and shipping, our team responds quickly and keeps information clear. Customers in cement, asphalt, power and water-treatment plants rely on our service to resolve problems without delay.

From the first technical discussion to installation and long-term maintenance, our team stays involved at every stage. We analyze your operating conditions, adjust product designs when needed, and ensure the final filtration setup works reliably in real plant environments. After delivery, our service team continues to provide guidance and troubleshooting support, helping you keep your system stable and downtime low.

Yes, we offer complete OEM/ODM services for liquid filtration, including:

Suitable for new filtration system development or upgrading existing equipment.

Yes, we provide free samples for standard PP/PE/mesh bags.

Customized bags can be produced within 2–4 days for fit and performance testing.

Typical micron selection guidelines:

Final selection depends on particle size, viscosity, and required clarity.

We supply multiple materials to match your liquid chemistry and temperature:

We offer full lifecycle support, including:

With 20+ years of experience and 1000+ global clients, we deliver stable filtration performance and dependable dust-collector operation.