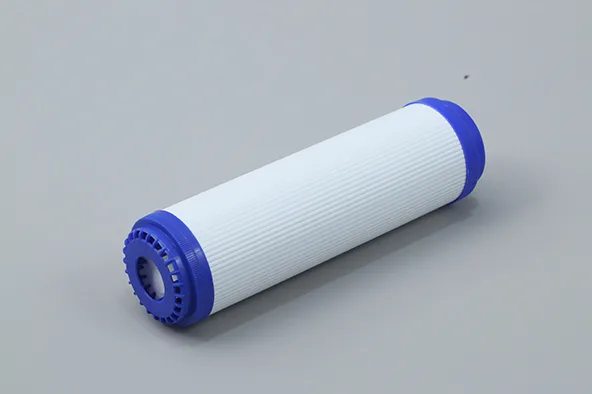

Pleated Membrane Filter Cartridges are high-precision, absolute-rated liquid filter elements that use microporous membranes (PES, PTFE, PVDF, Nylon) in a pleated structure to remove fine particles, colloids and microorganisms. They are best suited for final or pre-final filtration in applications demanding high purity and microbiological control – such as pharmaceuticals, food & beverage, bottled water, electronics, fine chemicals and RO/UPW systems.

When selecting Pleated Membrane Filter Cartridges, you must balance:

- Pore size / micron rating (typically 0.1–1.0 μm for critical steps)

- Membrane chemistry (PES, PTFE, PVDF, Nylon; plus PP support layers)

- Fluid type & temperature (WFI, CIP, solvents, beverages, corrosive media)

- Required sterility / bioburden reduction (sterile, bioburden control, clarification)

- Flow rate vs. allowable ΔP and filter area (pleat density & geometry)

- Target service life & integrity testing strategy

Omela Filtration supplies PES, PTFE, PVDF and Nylon pleated membrane cartridges engineered for high retention efficiency, wide chemical compatibility, validated integrity testing, and long on-stream life in demanding liquid-filtration duties.