Pre-Project Technical Evaluation

- Analyze dust chemistry, condensation risk, and corrosion level to decide if silicone coating is required.

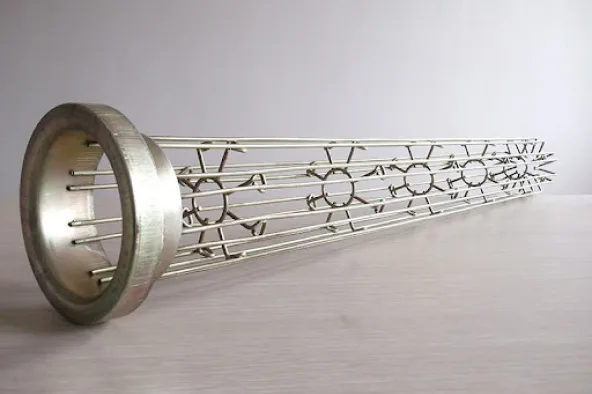

- Select base cage material: low-carbon steel for standard duty or SS304/SS316L for higher temperature and aggressive gases.

- Evaluate particle size, dust loading, stickiness, and pulse-jet cleaning intensity.

- Check compatibility with bag type (snap-band, sew-in, cuff), bag diameter/length, and venturi/collar design.

- Review temperature profile, dew point approach, and expected service life targets.