Water-Wastewater Treatment

Water & Wastewater Treatment Filtration Solutions

Water and wastewater treatment systems rely on robust filtration technologies to remove suspended solids, contaminants, organic matter, and pathogens from raw water sources and industrial effluents. Effective filtration is essential to ensure:

- Safe and compliant discharge into the environment

- Reliable drinking water quality

- Water reuse for industrial or agricultural purposes

- Reduced environmental impact and regulatory compliance

Filtration plays a crucial role in both municipal and industrial treatment plants, helping meet discharge limits and protect public health and ecosystems.

Water & Wastewater Treatment

Process & Filtration Challenges

Highly Variable Influent Characteristics

Wastewater streams vary widely in pollutant load, solids content, and organic matter depending on source (municipal, industrial, agricultural). Filtration solutions must be adaptable to these variations.

Fine Suspended Solids & High Turbidity

Even after primary and secondary treatment, effluent may still contain fine particles that impact water clarity and quality. Advanced filtration media are needed to capture particles down to sub-micron levels.

Biological and Chemical Contaminants

Certain contaminants like nutrients, bacteria, and dissolved organics require specialized filtration steps combined with adsorption and disinfection processes.

Sludge & Dewatering

Filtration systems often need to integrate with sludge handling and dewatering equipment such as belt filters and clarifiers.

Regulatory Compliance

Stringent effluent quality standards for discharge or reuse require reliability and consistency in filtration performance.

Engineered Filtration Solutions

Water-Wastewater Treatment Applications

Surface & Media Filtration

Media filters, such as sand, anthracite, or granular activated carbon (GAC), are widely used for solid removal in water and wastewater systems. These filters trap colloidal particles and contaminants while allowing clean water to pass through.

Membrane Filtration Technologies

Advanced membrane systems, including ultrafiltration, microfiltration, and reverse osmosis, provide high-precision separation for fine solids, bacteria, and dissolved contaminants when ultra-clean water quality is required.

Pile Cloth Media Filtration

Cloth-based filtration technologies offer efficient removal of organic and inorganic solids with continuous surface filtration and cleaning mechanisms, suitable for medium to large wastewater treatment scenarios.

Backwashing & Cleaning Strategies

Backwashing improves filter media longevity and prevents clogging by reversing flow through the media bed, often controlled automatically by head loss or pressure differential sensors.

Typical Water & Wastewater Treatment Processes & Filtration Challenges

| Process | Primary Contaminant | Particle / Contaminant Profile | Main Risk | Recommended Filtration |

|---|---|---|---|---|

| Raw Water Intake | Suspended solids, sand, debris | Coarse to medium particles; variable load depending on source | Pump wear, clogging of downstream equipment | Coarse screens + automatic backwash filters |

| Pre-Treatment / Primary Filtration | TSS, silt, organic matter | Fine suspended solids; fluctuating turbidity | Overloading of membranes or biological systems | Pressure sand filters or automatic fine filters |

| Biological Treatment (Activated Sludge) | Biomass, flocs | Soft, compressible solids; high water content | Solids carryover, poor effluent quality | Secondary clarification + polishing filtration |

| Tertiary / Polishing Treatment | Residual fine solids, colloids | Very fine particles; low concentration but high quality impact | Failure to meet discharge or reuse standards | Disc filters, cloth media filters, or cartridge filtration |

| Sludge Handling & Dewatering | Concentrated solids, polymers | High solids content; sticky or shear-sensitive | Equipment fouling, high disposal costs | Belt presses, centrifuges with filtrate polishing filters |

| Reuse / Discharge to Environment | Residual particulates | Low-level fines; compliance-critical | Regulatory non-compliance, environmental impact | Final polishing filters or membrane protection stages |

Filter Selection Guide for Water & Wastewater Treatment Applications

| Application | Preferred Collector Type | Filter Media Recommendation | Key Selection Notes |

|---|---|---|---|

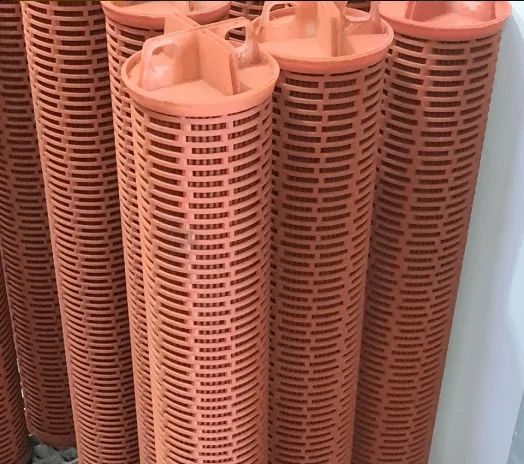

| Raw water intake / surface water screening | Self-cleaning screen / strainer (automatic) | Wedge wire / perforated screen (coarse removal) | Protect pumps and downstream filters; select screen gap by debris profile; ensure low pressure loss and reliable backwash |

| Pump protection / distribution booster stations | Simplex / duplex basket strainer | Stainless steel mesh basket (robust, washable) | Choose mesh size to prevent impeller wear; duplex option supports continuous operation during cleaning |

| Drinking water clarification (pre-filtration stage) | Pressure sand / multimedia filter (or equivalent) | Graded media bed (turbidity reduction) | Optimized for suspended solids removal; proper backwash rate is critical to avoid media fouling and channeling |

| Drinking water polishing (final barrier) | Cartridge filter housing | Depth PP melt-blown or pleated membrane cartridges (fine particulate) | Use as a final safeguard before distribution or sensitive equipment; verify micron rating and flow/ΔP curve for change-out planning |

| RO / UF pretreatment | Multi-stage: screen/strainer + cartridge | Depth + pleated cartridges (stable protection for membranes) | Goal is to reduce silt/solids loading to protect membranes; staged filtration lowers operating cost and reduces premature membrane fouling |

| Wastewater lift stations / influent protection | Coarse screen + self-cleaning strainer | Wedge wire / perforated screen (rags/fibers control) | Focus on clog resistance and reliable cleaning; plan bypass/maintenance isolation to prevent downtime |

| Aeration / biological treatment (side-stream protection) | Inline strainer / automatic filter | Stainless screen element (washable) | Protect valves, diffusers, and instrumentation; select for variable solids and bio-fouling tendency |

| Sludge dewatering (polymer prep / filtrate protection) | Cartridge / bag filter (service-friendly) | PP felt bags or depth cartridges (high dirt-holding) | Choose media for sticky solids and variable loading; prioritize easy change-out and stable ΔP to avoid process interruptions |

Reverse Osmosis Pre-Filtration Upgrade – Polypropylene Cartridge Filters

Combined Cycle Power Plant · Tarija, Bolivia

A combined cycle power plant in Tarija, Bolivia required reliable pre-filtration protection for reverse osmosis (RO) membranes used in water treatment systems supporting power generation.

The client operates laboratory services and imports filtration equipment, and specified strict technical requirements for depth-type polypropylene cartridge filters to ensure stable RO operation, membrane protection, and long service life.

Operating Conditions & Requirements

| Application | RO pre-filtration for power plant water treatment |

| Filter Type | Depth cartridge filter (thermally bonded PP fibers) |

| Micron Ratings | 1 µm and 5 µm |

| Filter Length | 40" (1016 mm) |

| Outer Diameter | 2.5" – 2.6" (63.5 – 66.04 mm) |

| Inner Diameter | 1.0" – 1.1" (25.4 – 27.94 mm) |

| Max Differential Pressure | ≥ 2.0 bar @ 20 °C |

| Max Operating Temperature | ≥ 60 °C |

| Material Certification | NSF / ANSI 42 (traceable & verifiable) |

Omela Filtration Solution

- Thermally Bonded PP Depth Cartridge Design

– Melt-blown / spun-bond polypropylene fibers for consistent pore structure - Optimized 40" High-Surface-Area Configuration

– Lower pressure drop and extended service intervals - Dual Micron Strategy (5 µm + 1 µm)

– Staged particulate removal for enhanced RO membrane protection - NSF-Certified, Water-Safe Construction

– No fiber release, no chemical impact on water quality

Measured Results

| Parameter | Before Optimization | After Omela Solution |

| RO Membrane Fouling | Frequent clogging risk | Significantly reduced fouling |

| Pressure Drop Stability | Inconsistent during solids spikes | Stable ΔP within design limits |

| Cartridge Structural Integrity | Collapse risk under high loading | ≥ 2 bar collapse resistance |

| Maintenance Frequency | Frequent cartridge replacement | Extended service life |

| RO System Reliability | Operational interruptions | Stable, continuous operation |

“The supplied polypropylene cartridge filters fully meet our dimensional and performance requirements. RO system stability has improved, and membrane protection is now consistent under normal operating conditions.”

— Water Treatment Engineer, Combined Cycle Power Plant, Bolivia

Reduce

Filtration Costs

Significantly

Longer bag life, fewer change-outs, and lower total cost of ownership (TCO). Let our experts show you how much you can save.

Frequest Asked Questions

Pretreatment is designed to remove suspended solids, sediments, and particulate contaminants before fine filtration or membrane processes such as reverse osmosis (RO). Effective pretreatment protects downstream filters and membranes, stabilizes differential pressure, and significantly extends RO membrane service life.

Depth cartridge filters—typically polypropylene melt-blown cartridges rated at 5 µm and 1 µm—act as the final protective barrier before RO membranes. They remove fine particulates that could cause membrane fouling, plugging, or irreversible damage, ensuring stable operation and consistent permeate quality.

Liquid filter bags are not a replacement for RO pre-filtration cartridges, but they are highly effective as an upstream pretreatment stage. When installed before cartridge filters, polypropylene felt filter bags (10–50 µm) remove larger suspended solids, reduce cartridge loading, and lower overall operating cost (TCO).

Woven polypropylene filter fabrics are typically used in coarse pretreatment stages, such as:

- Raw water intake

- Surface water filtration

- Circulating water systems

- Industrial wastewater pretreatment

They are not recommended as the final filtration step before RO, but they are valuable for bulk solids removal ahead of sand filters, filter bags, or cartridge filters.

Polypropylene (PP) is widely used in water and wastewater pretreatment because it:

- Is chemically inert and does not affect water quality

- Offers excellent resistance to acids, alkalis, and most chemicals

- Has good thermal stability for typical process water temperatures

- Does not shed fibers when thermally bonded or properly finished

These properties make PP suitable for RO pretreatment and power plant water systems.

A staged filtration design—woven fabric → liquid filter bag → depth cartridge— distributes solids loading across multiple filtration levels. This approach:

- Slows pressure rise on cartridge filters

- Extends cartridge replacement intervals

- Reduces unplanned maintenance

- Lowers total cost of ownership (TCO)

It also improves system reliability under high turbidity or variable feed water conditions.

Typical micron ratings include:

- 50–200 µm: Woven filter fabric (coarse pretreatment)

- 10–50 µm: Liquid filter bags (intermediate pretreatment)

- 5 µm / 1 µm: Depth cartridge filters (final RO protection)

Proper selection depends on raw water quality, system flow rate, and membrane protection requirements.

Yes. Multi-stage pretreatment using PP filter bags, woven fabrics, and depth cartridges is widely applied in:

- Combined cycle power plants

- Boiler feedwater systems

- Cooling water pretreatment

- Industrial process water systems

These solutions are designed to support continuous operation, stable pressure drop, and compliance with industrial water quality standards.

By removing particles before they reach the membrane surface, pretreatment filters:

- Prevent irreversible membrane fouling

- Reduce chemical cleaning frequency

- Maintain stable transmembrane pressure

- Extend membrane service life

This directly improves system uptime and operational efficiency.

Pretreatment selection should be based on:

- Feed water quality and turbidity

- Particle size distribution

- Flow rate and operating pressure

- RO membrane sensitivity

- Maintenance and cost targets

A properly engineered pretreatment system balances filtration performance, reliability, and lifecycle cost rather than relying on a single filter type.