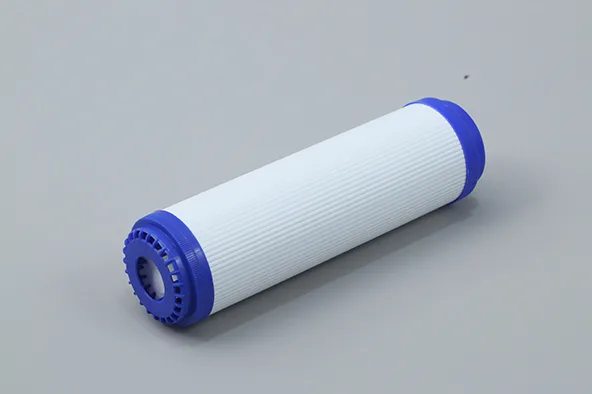

String wound filter cartridges are a type of depth filtration element made by tightly winding high-quality fibers around a porous core to form a gradient density matrix that traps contaminants throughout its depth. This winding pattern creates a progressively tighter pore structure from the outside to the inner core, enabling large and fine particles to be captured efficiently without rapid pressure rise. This design delivers high dirt-holding capacity, low differential pressure, and long service life in a wide range of liquid filtration applications.

Key Features & Benefits

- True depth filtration matrix with gradient density for efficient particle capture.

- High dirt-holding capacity enables longer cartridge life and fewer replacements.

- Low differential pressure helps maintain system flow and reduces energy consumption.

- Broad chemical compatibility (depending on yarn material selection).

- Wide micron range available (typically 0.5–200 µm) to match diverse filtration needs.

- Multiple core options provide structural integrity, including PP or stainless steel cores.

String wound cartridges provide an economical solution for coarse to medium filtration duties, especially in applications where large volumes of fluids must be processed cost-effectively. Their true depth filtration mechanism ensures contaminants are trapped both on the surface and deep within the wound fiber matrix, extending service intervals and reducing operating cost.