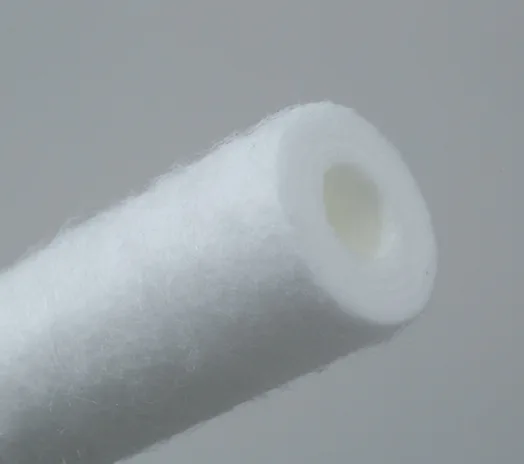

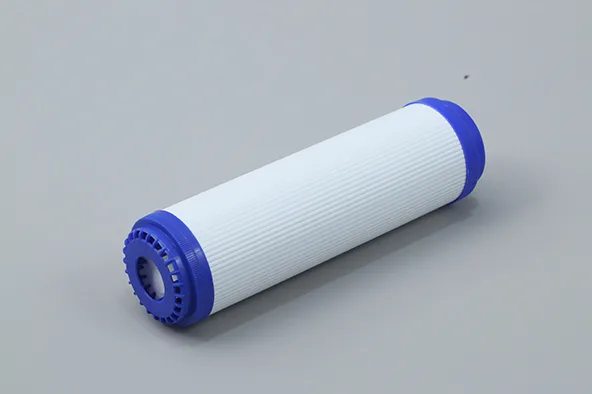

Melt-Blown Filter Cartridges are polypropylene depth filter elements constructed from thermally blown microfibers into multi-layered gradient density media. They deliver progressive depth filtration, high dirt-holding capacity, stable pressure drop, and wide chemical compatibility for industrial liquid filtration. Ideal for RO/UF prefiltration, municipal and industrial water treatment, sediment control, and general process liquid clarification. Their layered depth matrix holds particles throughout the media rather than only on the surface, extending service life while reducing operating cost.

Melt-blown cartridges consist of multiple layers of melt-blown microfibers with a controlled gradient density — coarser fibers on the outer layers transitioning to finer fibers inward. This structure:

- Captures larger suspended solids first, then progressively finer particulates

- Maximizes dirt-holding capacity while stabilizing pressure drop

- Minimizes fiber migration and enhances structural integrity

The melt-blown production process uses high-speed air to extrude molten polypropylene into fine fibers that collect on a rotating mandrel, forming a porous, depth filter medium with graded pore sizes.

Unlike some wound or media-bonded filters, melt-blown cartridges involve thermal bonding without adhesives or lubricants, reducing the risk of contaminants from the media itself — a benefit especially valued in food, beverage and potable water applications.