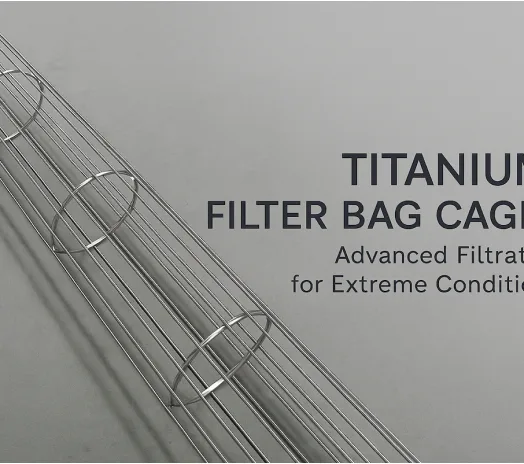

Titanium Filter Bag Cages are ultra-corrosion-resistant, lightweight, high-strength structural frames designed for the most aggressive industrial environments. Installed inside filter bags, they maintain shape under airflow, ensure stable dust collection efficiency, and tolerate strong pulse-jet cleaning impacts.

Engineered for chloride-rich, acidic, alkaline, marine, high-humidity, or chemically aggressive atmospheres,titanium cages offer significantly longer service life and reliability compared to carbon steel, galvanized steel, or even stainless steel options.

Key selection criteria

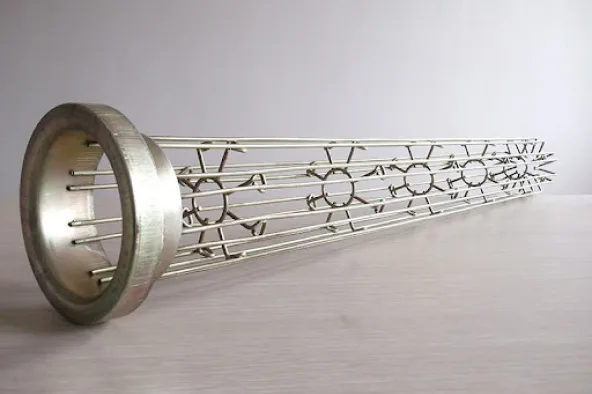

- Material grade: Titanium Grade 2 / Grade 5

— Exceptional resistance to acids, alkalis, chlorides, and seawater—ideal for highly corrosive environments. - Temperature resistance: up to ~300 ºC

— Maintains strength and corrosion resistance under continuous thermal cycling. - Wire diameter: 3.0–5.0 mm (high rigidity)

— Lightweight yet strong; provides excellent dimensional stability during pulse-jet cleaning. - Number of vertical wires: 8 / 10 / 12 / 16 / 20 / 24

— Higher wire counts improve rigidity and prevent filter bag deformation. - Ring spacing: 6″ or 8″

— Ensures stable airflow and reduces wear on the filter media. - Cage shapes: Round, Oval, Diamond, Pleated/Star

— Selected based on baghouse layout, dust characteristics, and required filtration efficiency. - Surface characteristics: Smooth welds, polished, burr-free

— Prevents abrasion and significantly extends filter bag service life.