Galvanized Steel Filter Bag Cages are cost-effective, corrosion-protected support structures designed to maintain filter bag shape, ensure smooth airflow, and withstand the mechanical force of pulse-jet cleaning. They are widely used in cement plants, boilers, steel mills, grain dust systems, carbon black, and general industrial dust collection where moderate corrosion levels exist and long service life is required at a competitive cost.

Zinc Coating Quality

- Hot-dip galvanizing (highest corrosion resistance; thick zinc layer).

- Electro-galvanizing (smooth finish; economical; good for indoor systems).

- Provides protection against rust, humidity, condensation, and mild chemical exposure.

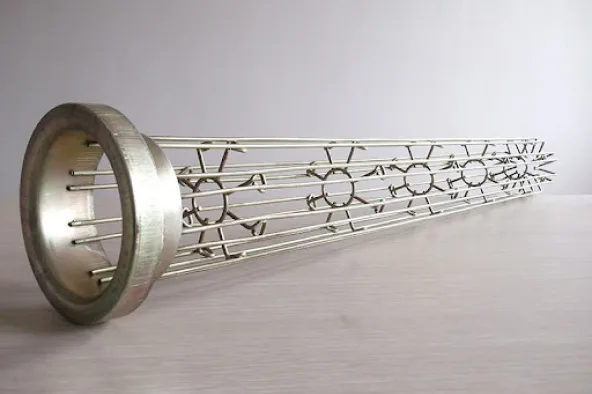

Mechanical Specifications

- Wire diameter: 3.0–5.0 mm

- Vertical wires: 8 / 10 / 12 / 16 / 20 / 24

- Ring spacing: 6″ or 8″ for controlled airflow and minimized bag abrasion

- Cage shapes: Round, oval, diamond, pleated/star

- Diameter options: 100–200 mm

Surface & Structural Features

- Smooth, burr-free welds to protect filter bag fabric

- Straightness and ring alignment ensure low pressure drop & stable filtration performance

Compatibility & Connection Types

- Suitable for snap-band, sew-in, or cuff-style bags

- Optional components:

- Venturis (steel or aluminum)

- Collars, flanges, clamps

- Custom cage lengths and multi-section designs