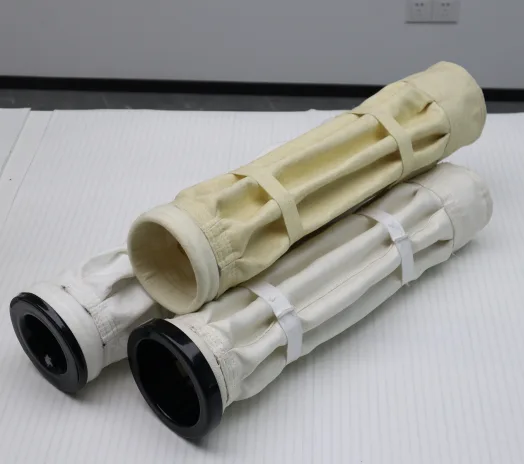

Pleated filter bags are engineered to upgrade traditional baghouse performance by combining the surface area and rigidity of a cartridge-style element with the dimensional flexibility of a fabric filter. Pleated bags are widely used in cement mills, grain processing facilities, powder coating lines, pharmaceuticals, metalworking, and general industrial dust collection, where fine particulate and high dust-loading conditions require stable airflow and longer service life.

Key Design Advantages

- Combine the structure of cartridge filters with the adaptability of fabric bags

- Replace longer felt bags with shorter pleated elements

- Provide 2–3× more filtration area in the same space

- Improve airflow distribution and dust collection efficiency

- Reduce system pressure drop and overall fan energy consumption

- Ideal for retrofits where air-to-cloth ratio is insufficient

- Maintain rigidity through an integrated reinforced internal core