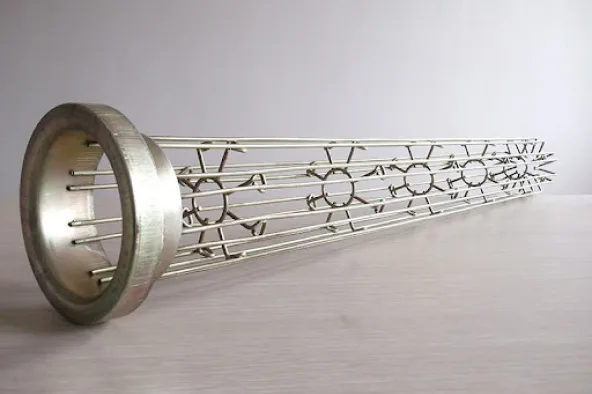

Stainless Steel Filter Bag Cages are high-strength, corrosion-resistant structural frames installed inside filter bags to maintain shape, ensure stable airflow, and withstand pulse-jet cleaning impacts. They are engineered for high-temperature, corrosive, abrasive, or moisture-rich industrial environments, providing superior durability and service life compared to carbon steel or galvanized cages.

Key selection criteria:

- Material grade:SS 304 / SS 316L — Excellent corrosion resistance, suitable for acidic, alkaline, or oxidizing atmospheres.

- Temperature resistance:up to 400–500 °C — Stable under continuous high-temperature cycles.

- Wire diameter:3.0–5.0 mm (high rigidity) — Thicker wires ensure structural integrity during pulse-jet cleaning.

- Number of vertical wires:8 / 10 / 12 / 16 / 20 / 24 — Higher wire count improves rigidity and prevents bag deformation.

- Ring spacing:6″ or 8″ — Ensures airflow stability and minimizes fabric wear.

- Cage shapes:Round, Oval, Diamond, Pleated/Star — Selected based on baghouse design and particulate loading.

- Surface characteristics:Smooth welds, burr-free, polished finish — Prevents abrasion and significantly extends filter bag life.

Omela’s precision-manufactured stainless cages ensure stable filtration efficiency, lower total operating cost (TOC), and long-term reliability even in the most demanding dust-collection environments.