Baghouse Fluorescent Tracer Powder

Baghouse Fluorescent Tracer Powder

Baghouse Fluorescent Tracer Powder Oveview

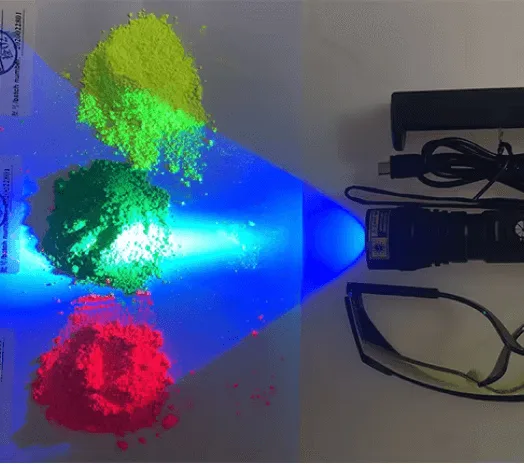

Baghouse Fluorescent Tracer Powder is a high-visibility diagnostic powder engineered for baghouse leak testing, emission troubleshooting, broken bag detector, and airflow pattern analysis. When introduced into the dust collection system, its fluorescent characteristics allow maintenance teams to instantly identify filter bag tears, faulty seams, misaligned cages, tube sheet leaks, and bypass points under UV inspection.

Key Selection Criteria

- Temperature resistance (up to 230–300°C depending on formulation)

- Color visibility (pink, yellow, green UV-reactive)

- Particle size uniformity for clear deposition patterns

- Compatibility with dust composition & bag media

- Detection sensitivity for micro-leak pathways

- RoHS compliance — free of restricted substances under EU hazardous materials regulations

Omela Filtrations provides engineered diagnostic powders optimized for high-temperature, corrosive, and fine-dust industrial environments—enabling faster leak detection, more reliable shutdown planning, and lower emissions.

Baghouse Fluorescent Tracer Powder – Technical Specifications

| CAS No. | 25035-72-7 | Place of Origin | China |

| Model | OM-11 | Brand | Omela |

| EINECS No. | 215-168-2 | Alias | Fluorescent Pigment |

| Category | Organic Pigment | Type | Other |

| Application Field | Pigment for plastics (rubber) | Product Name | Fluorescent Leak Detection Powder |

| Color | Pink / 12 colors available | Particle Size | 3 μm |

| Heat Resistance | ≤ 280°C | Application | Leak Detection |

| Minimum Order Quantity | 5 KG | Packing | 25 kg/drum or 5 kg/drum |

| Packaging & Shipping Information | |||

| Packaging Details | 1. Inner Packaging: Polyethylene bag 2. Outer Packaging: Carton box Available in 3.1 kg / 5 kg / 10 kg / carton | ||

| Package Size (Single Unit) | 26 × 26 × 29 cm | Gross Weight (Single Unit) | 6.5 kg |

| Sales Unit | Single Product | ||

INDUSTRIAL

APPLICATIONS

Engineered to protect filter bags during system startup and early operation, Baghouse Fluorescent Tracer Powder helps maintenance teams quickly identify leakage paths, verify installation quality, and optimize emission control performance. Ideal for high-dust, corrosive, and high-moisture environments requiring consistent filtration stability.

Cement, Lime & High-Dust Baghouses

Used during kiln startup, clinker line transitions, and high-dust conditions to track bypass leakage, verify new bag installations, and detect early failures in high-alkaline, fine-dust environments.

Steel Plants, Metallurgy & Foundry Exhaust

Applied in EAF, sinter plants, and foundry dedusting systems to locate leaks around tube sheets, expansion joints, and weld seams in hot, corrosive fume streams.

Waste-Incineration, Power Generation & Chemical Processing

Ideal for boilers, waste-to-energy units, and chemical scrubber systems to confirm bag integrity after outages and to troubleshoot unexplained emission spikes.

Why Choose Omela Filtration?

Choosing the right filtration supplier affects everything from system stability to maintenance downtime. At Omela Filtration, we combine reliable materials, controlled production, and years of industry experience to support dust and liquid filtration needs across different plants and applications.

We use consistent-grade filter media, sewing thread and metals sourced from qualified suppliers. Each batch is checked for weight, thickness, air permeability and tensile strength to keep performance steady across shipments.

Our facility is equipped with modern sewing lines, hot-welding machines and automated inspection tools. This keeps production efficient and helps us meet tight delivery schedules, even on custom orders.

Our engineers and technicians have long experience with dust collectors, liquid systems and industry-specific conditions. They help you match materials to temperature, chemistry and air-to-cloth ratios to avoid unnecessary failures.

From sampling to documentation and shipping, our team responds quickly and keeps information clear. Customers in cement, asphalt, power and water-treatment plants rely on our service to resolve problems without delay.

From the first technical discussion to installation and long-term maintenance, our team stays involved at every stage. We analyze your operating conditions, adjust product designs when needed, and ensure the final filtration setup works reliably in real plant environments. After delivery, our service team continues to provide guidance and troubleshooting support, helping you keep your system stable and downtime low.

Frequest Asked Questions

Related Products

Trusted by Industries

Worldwide

Backed by 20+ years of experience and 1000+ clients, Omela Filtration provides dependable solutions for both industrial liquid filtration and dust-collection systems—ensuring stable performance, efficiency, and long-term reliability.