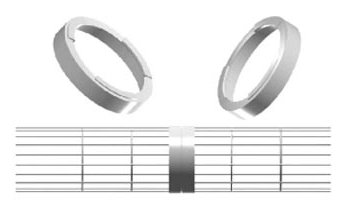

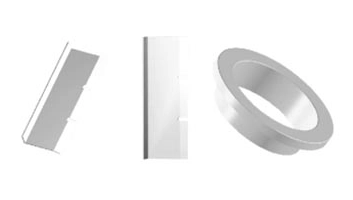

Filter Bag Cage Collars

- Available in carbon steel, galvanized steel, stainless steel (304/316), or aluminum depending on corrosion and temperature conditions

- Ensures secure connection between filter bag and cage for stable sealing and leak-free performance

- Designed to match various baghouse systems (snap-band, clamp-band, or cuff-type connection)

- Precision-formed for dimensional accuracy to prevent bag abrasion and ensure long service life