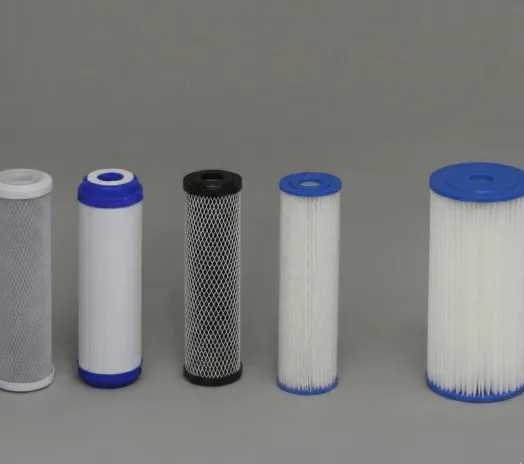

Carbon filter cartridges are activated carbon-based filtration elements designed to significantly improve water quality by adsorbing dissolved contaminants, chlorine, taste, and odor from water streams. They are widely used in drinking water treatment, municipal and industrial water systems, and RO pre-treatment where chemical adsorption and polishing are essential.

Why Carbon Filter Cartridges Are Important

In many filtration systems, particulates are first removed by sediment or depth filters, but dissolved contaminants and undesirable tastes remain. Carbon filter cartridges provide the adsorption stage to:

- Reduce chlorine, chloramines, and disinfection by-products

- Remove organic compounds, pigments, and VOCs

- Improve water taste, smell, and clarity

- Protect downstream equipment from chemical fouling

This makes them a crucial part of drinking water systems, bottles & coolers, whole-house filtration, and industrial process water polishing.